Part 7. Edwears Prada – his new Framework

This week I’d like to admit something to you. When

This week I’d like to admit something to you. When

In 1983, the Times magazine cover depicted a robot carting

I remember how all entrepreneurs began their adventure with the

To standardise or to automate – that is the question.

I’m smart, I’m courteous – I’m already well prepared to

As you know from the first episodes, I’m quite unusual.

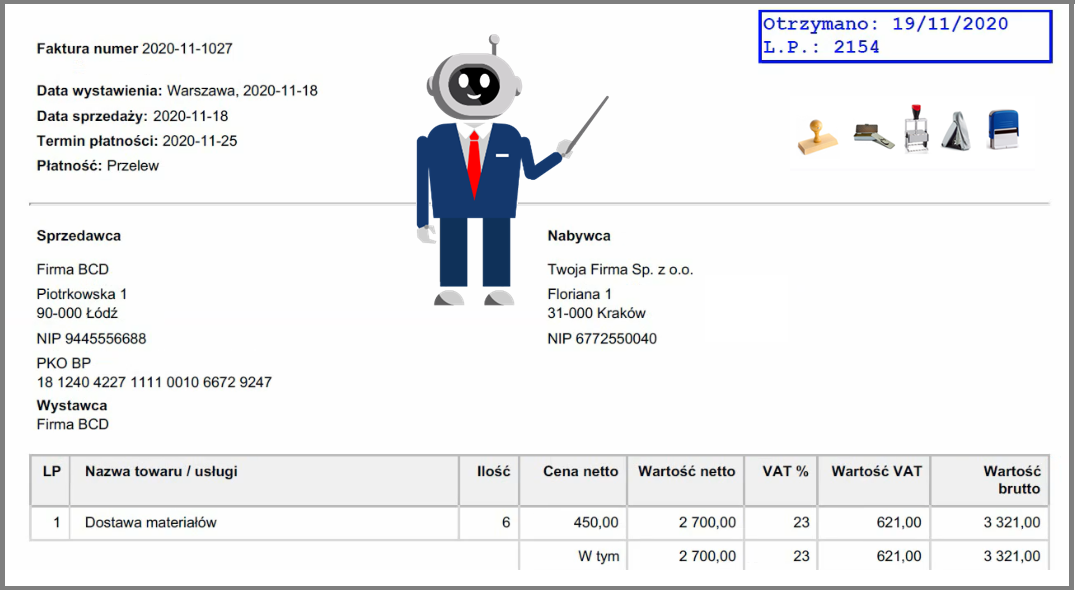

Today, I would like to show how we can “affix

I’m Robotowsky… Ed Robotowsky. I know, it sounds like a

Searching the foreign databases of contractors. Withholding tax is a